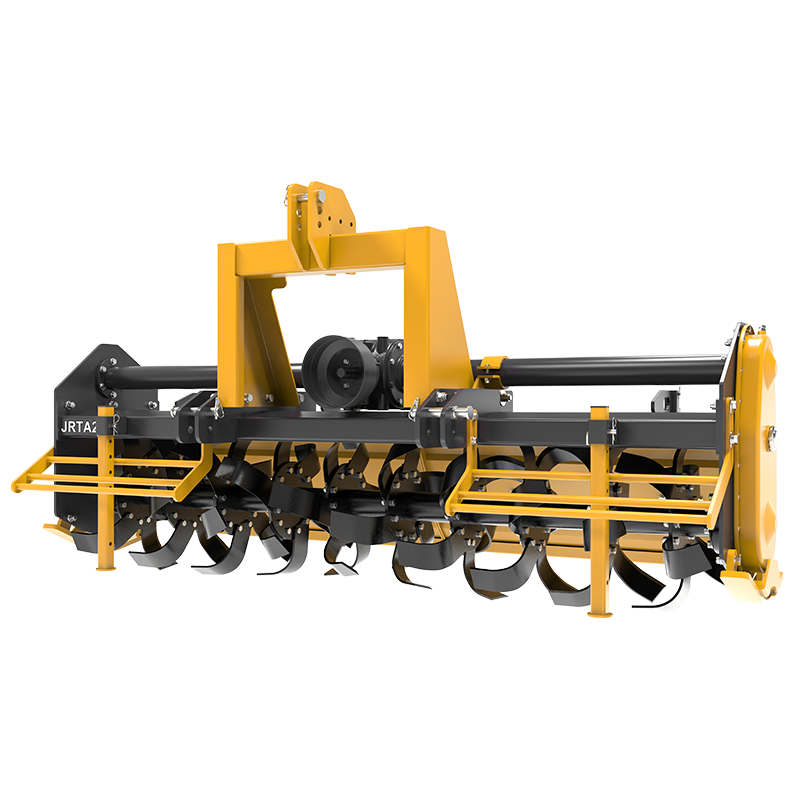

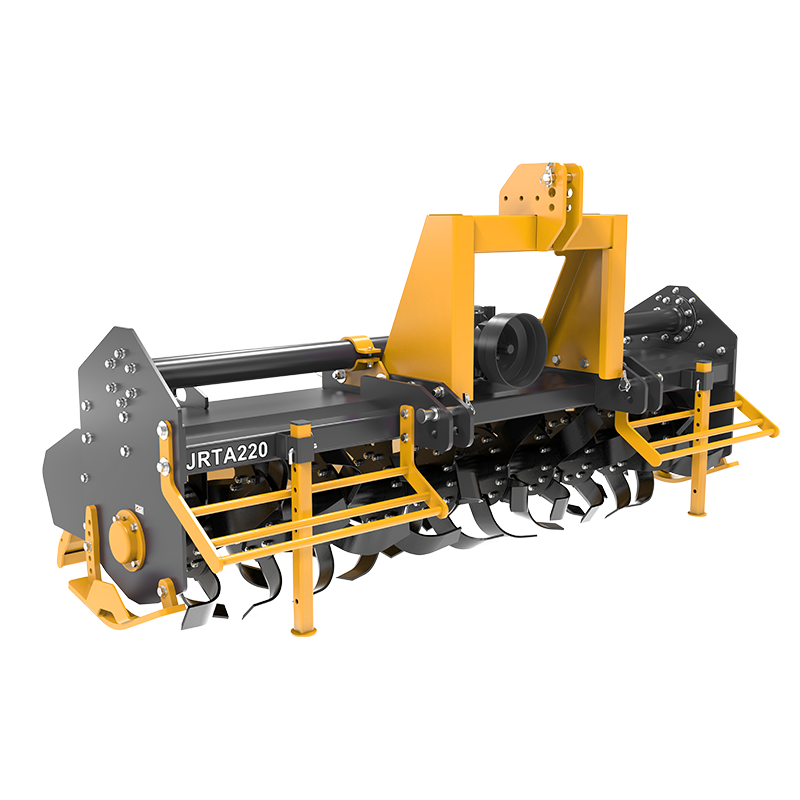

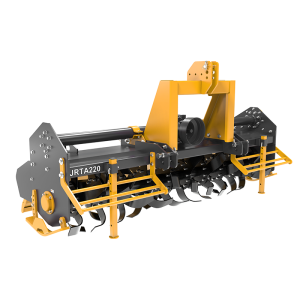

It has been widely used because of its strong ability to break soil and the flat surface after plowing. It can also chop the root stubble buried below the surface, which facilitates the operation of the seeder and provides a good seed bed for later sowing.

1.At the beginning of the operation, the rotary tiller should be in the elevated state, first combine with the power output shaft to increase the blade shaft speed to the rated speed, and then lower the rotary tiller so that the blades gradually penetrate into the soil to the required depth. It is strictly prohibited to combine the power output shaft or sharply lower the rotary tiller after the blade is inserted into the soil, so as to avoid bending or breaking the blade and increasing the load on the tractor.

2.During operation, the machine should be driven as slowly as possible, which can not only ensure the quality of the operation, break the soil into fine pieces, but also reduce the wear of the machine parts. Pay attention to whether there is any noise or metal knocking sound from the rotary tiller, and observe the soil breaking and plowing depth. If there is any abnormality, the machine should be stopped immediately for inspection and operation can be continued only after troubleshooting.

3.When turning at the edge of the field, it is forbidden to work. The rotary tiller should be raised to keep the blades off the ground, and the tractor’s throttle should be reduced to avoid damaging the blades. When lifting the rotary tiller, the inclination angle of the universal joint should be less than 30 degrees. If it is too large, impact noise will be produced, causing premature wear or damage.

4.When reversing, crossing field ridges and transferring plots, the rotary tiller should be raised to the highest position and the power should be cut off to avoid damage to the machine parts. If it is moved to a distant place, the rotary tiller must be fixed with a locking device.

5.After each shift, the rotary tiller should be maintained. Remove the soil and weeds from the blade, check the tightening of each connection, add lubricating oil to each lubricating oil point, and add butter to the universal joint to prevent increased wear.

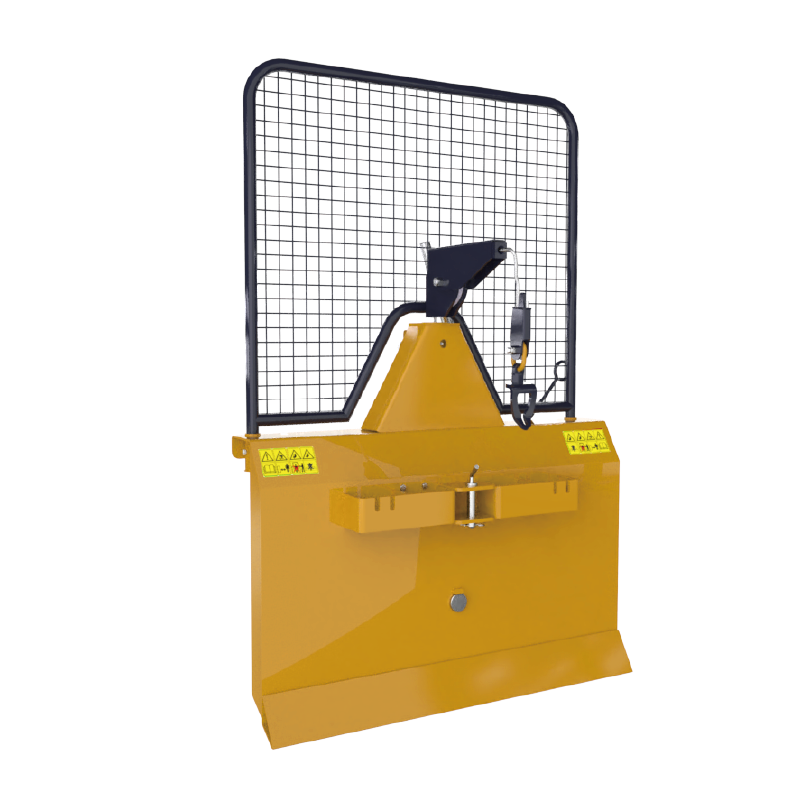

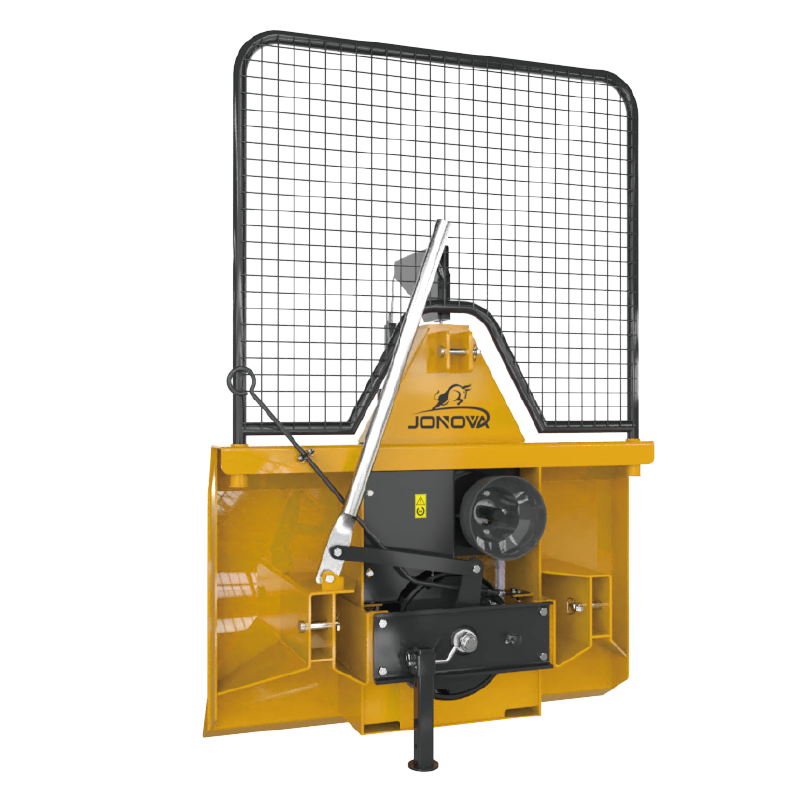

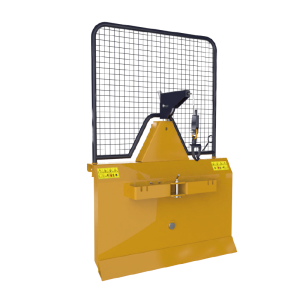

The rotary tiller has a spring to adjust the height of the back cover to ensure that the soil is broken more evenly during operation. The front part is equipped with a safety guardrail to ensure the safety of the operator. It is equipped with a high-quality gear box and a double support system, which is sturdy and durable. The side gearbox cover has an open mold design and a high-strength seal, so there is no gear oil leakage. High-strength slide rail plates are used in various complex working environments. The blades are made of high-strength materials, can be used for a long time, and are easy to replace. Before shipment, each model undergoes extensive testing to ensure the quality of the machine.